This page covers the self designed, custom built SP-500

Page Sub Links: Specs Construction Photos Corvair CAD 1/4 Scale Model

3 View

Driveway Assembly of all the major parts.

6G proof load test @ 95ºF 90% Humidity

The original concept for the SP-500 was conceived Jr & Sr years while I was finishing up my BSAE at Embry Riddle. I could not get enough of the Sr. Design classes for the Aeronautics path. for preliminary design we worked on new 2 to 4 seat General Aviation Aircraft, detail design was a unique opportunity to “On-Campus” internship with Gulfstream, working on what is now the G550 window structure concept optimization. I adsorbed everything I could learn and spent countless hours in ERAU DB massive Aviation Library. Although I did not know it while I was there, one of the most influential contact’s I’ve made on Home Built aircraft / “your own design – manufacturing capability with in” was an ERAU Alumni and lived in the same county, more on this later.

Back to the 500, it was my own after hours project during the day while learning / adsorbing prelim & detail task while also being the designated “CAD Guy” I rapidly got good at Catia V5, students could use the software in the computer labs, usually after 5 for there own use, I doodled up many fantastic / unlimited budget aircraft, but the 500 remained as the with resources permitting what could I really do Airplane.

Here are some screen shots of my lofty goal airplanes on Catia V5

PT-6 Powered military ground support / training tandem seat.

M-14P powered, Spartan Executive inspired All Composite 4 Seater (Living in So Fla now I Just may find some investors for this one)

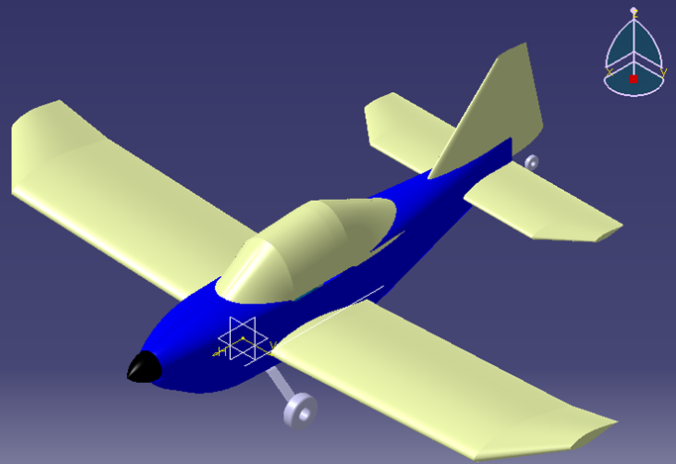

one of the earliest 3D Cad Models of the 500, since then the devil is in the details, and there is a ton of details

Mid Life Model with more refinements.

The 500 remained a dormant Idea for a few years, When I started with Piper Aircraft in Vero Beach early in 05′ I quickly joined the Local EAA 99 Chapter. they had a Kit Fox project that was donated to them and I volunteered to take on efforts to get the project started, It had been sitting for quite some time and all the parts have become quite dirty and diss organized, I cleaned and organized all the parts the best I could, got familiar with all the components & Manual, was not too much of a stretch since the Avid Magnum that I have a good amount of Kit & Flying experience with was similar. While it was a good experience I knew that the Kit Fox was just another typical home built that was just too small for me.

While going to the monthly 99 meetings I met Bill Zorc a Pilot for UPS who flies the Atlantic routes to Europe, He had been involved in the Corvair Auto to Aero conversion for a while now using William Wynne’s manual, this was all new to me knowing only about Lycomings, Continentals, & PT-6’s, there was a public engine build and education event called a Corvair College in Edgewater Fl just south of Daytona for all places that he invited me to. this happened to be the spark that turned the 500 from a “paper project” into the real deal.

Overview Shot from CC #9 (from the flycorviar.com site)

Like the light bulb that went off all those years before in Oshkosh 93′ when it came to you can do Aircraft Composites, this was a even more profound one. The big barrier that has all ways snuffed out any hope of owning and building my own plane is the monumental up front cost for the kit & the Engine.

This event was a 180 from what Oshkosh & Sun-n-fun have become = a spectator event where the wealthy flex & show off there wallets.

of particular attention was Mark & Bills KR-2s, Dan W’s Sonex and 601’s all very similar to the 500, flight demonstrations where extremely impressive showing demonstrated flight performance with multiple engines & airframes not trailed in slimy sales men smoke and mirror tricks. The Corvair Conversion was a totally new concept to me a pay as you go plans built engine, with a total cost way less than even a salvage yard brand L, C or F engine before over hall.

the 2nd part of the puzzle was some exposure to plans build composite aircraft beyond the “ez – RAF canards” particularly Mark Langford’s KR-2 where I learned he has a very informative & documented web site for his build http://www.n56ml.com

I left the event with a wave of motivation and the overwhelming idea in my head that I can do this!

At first I knew I wanted the Corvair but was not quite convinced that the 500 was the airframe. I quickly ordered the conversion manual and located cores near buy in Plant City near Lakeland Fl.

My core diss assembly, a gooie adventure but a treasure was underneath.

The RC model:

Sr year at ERAU I started to build a 1/4 scale RC model of the 500, I made some small changes including going from a crude bubble style canopy to a fast back, by the time I stared with Piper the Model was ready to fly

Flight Qualities where Amazing, perfect handling, easy spin recovery, decent Acrobatic ability. From ERAU wind tunnel lab I knew the 2 things I could learn was basic stability & control and CG placement going from full scale to a model. I even tuff Tested the left wing with a live down link video camera capturing it all

The model did float in ground effect excessively, but the over all conclusion is it was one great flying aircraft, and some day I would want to build it.

Working for Piper at the time & being in the company flight club allowed me 24/7 immersion into all things aviation. Not long after the picture above was taken, on one of the many trips between the Engineering building & Final Assembly thinking about the flight of the RC model the reality hit, the 500 was the plane to build, my college side project that I have slowly been dabbling with on the paper world side. After all I was in the daily business of turning rough napkin concepts in to FAA Certified / Production reality!, like the side job in College working on the 500, so it has again but this time with some serious attention to detail.

The true detail design work is done in a real old copy of AutoCad r14, I have had formal drafting training so a good 2D software was I needed. lay it out full scale on the computer and have the ability to print out simple drawings & full size templates.

Interesting concept on the Spartan. Have you done any more with this?

Regards,

Norm Parmley

nparmley@suddenlink.net

LikeLike

Norman,

Did some more work on a Tandem seat M14P sized aircraft, mostly Rhino practice but it has promise as well

I placed a downloadable cad file on https://grabcad.com/library/m14p-tandem-1

Seeing that several old radial planes could be turned into tubro prop’s weight and balance / prop clearance wise like the Turbo Beaver / Otter that could be another option for a common airframe

Spencer

LikeLike